To improve anything in your business, you first need to understand the question: what is process improvement in business? Without that clarity, many improvement efforts start with good intentions—and end in more confusion, frustration, and wasted effort.

I see this all the time. Business owners know something isn’t working, so they jump straight into fixing things without a clear plan. The result? More chaos, disengaged employees, and customers who feel the inconsistency.

Process improvement isn’t about changing everything at once. It’s about improving how work gets done—on purpose, and in the right order.

What Is Process Improvement in Business?

Process improvement in business is the practice of analyzing how work is currently done and making targeted changes to reduce waste, errors, delays, and frustration.

When done properly, process improvement helps you:

- improve efficiency

- reduce rework and bottlenecks

- deliver more consistent results

- improve employee morale

- improve customer experience

This applies to every type of business—including trades and service businesses that often overlook internal processes because “that’s just how we’ve always done it.”

Why Process Improvement Often Fails

One of the biggest mistakes businesses make is treating process improvement as a one-time fix.

Common reasons process improvement initiatives fail include:

- no clear ownership

- trying to fix too much at once

- poor communication with staff

- lack of follow-through

- changes that don’t match how the business actually operates

Improvement fails when it’s rushed or disconnected from real workflows. It succeeds when it’s structured, realistic, and supported by the people doing the work.

How to Start Process Improvement in Your Organisation

You don’t need a massive program to start. You need a clear improvement process.

Here’s a practical, step-by-step approach that works for small and growing businesses.

Step 1: Build the Right Process Improvement Team

Process improvement is not a solo effort.

You need a small team that:

- understands how the work is actually done

- is respected by others

- is open to change

- can influence outcomes

Choosing the wrong people can stall progress before it starts. Take the time to explain why improvement matters and what success will look like.

Step 2: Identify Which Processes Need Improvement

Not every process needs fixing—and not all at once.

Common candidates include:

- hiring and onboarding

- order processing

- scheduling and dispatch

- inventory management

- customer service workflows

Ways to identify improvement opportunities:

- conduct simple process audits

- review performance metrics (cycle time, errors, delays)

- analyze customer feedback

- ask employees where work breaks down

Your team usually knows where the problems are—you just need to ask.

Step 3: Compile and Prioritize the Findings

This step is often skipped—and it shouldn’t be.

Collect everything into one list, then prioritize:

- which issues cause the most disruption

- which are easiest to fix

- which deliver the biggest impact

This prevents the “wish list” problem where everything feels urgent.

Step 4: Set Clear Improvement Goals

Before making changes, define what success looks like.

Use SMART goals:

- Specific

- Measurable

- Achievable

- Relevant

- Time-bound

Clear goals keep improvement aligned with business objectives and make results easier to track.

Step 5: Map the Current Process

You can’t improve what you don’t understand. Before you can begin to improve your business processes, it’s important to have a clear understanding of how they currently work.

Mapping out your existing processes can help you identify inefficiencies, find bottlenecks, standardize processes and areas for improvement.

To map out your existing processes will require an expert to get it done right. This is a critical piece of the work and is where the services of a business processes specialist such as BCINC will help you tremendously as they can get this done quickly and efficiently.

Process mapping helps you:

- see bottlenecks clearly

- identify duplicate steps

- uncover handoff issues

- standardize workflows

This step is often where businesses benefit the most from outside support, because it’s especially easy to miss inefficiencies when you’re too close to the work.

Step 6: Analyze the Process

Once mapped, analyze the process for:

- delays

- rework

- unclear responsibilities

- data gaps

- resistance points

This analysis helps you decide what to fix first, instead of guessing.

Step 7: Brainstorm Practical Solutions

Now involve the team.

Employees doing the work often have the most practical ideas. Involving them:

- improves solution quality

- increases buy-in

- reduces resistance to change

Keep solutions simple and realistic.

Helpful Resources for Brainstorming

ROCKETBOOK Smart Reusable Notebook Wireless

Capture findings and action steps fast

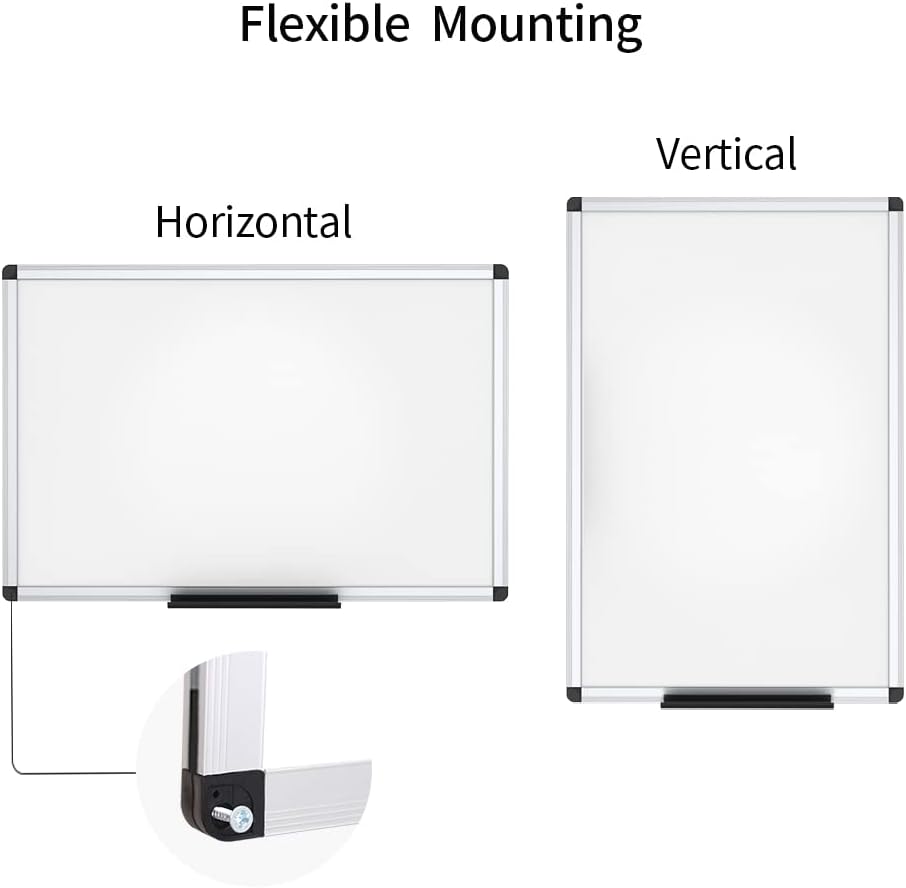

VIZ-PRO Dry Erase Magnetic Board

Map workflows and bottlenecks visually

Step 8: Evaluate and Select the Best Solutions

Before implementation, review each option:

- What will be the success criteria for this solution?

- Analyze the cost vs benefit

- What resources will be needed to execute this solution?

- How will you implement?

- Assess the risks

- Ease of adoption

- How will progress be monitored?

- Prioritize solutions

- Finally, identify your top priority improvement to start with

Finally, identify your top priority improvement to start with

Step 9: Implement the Changes

Implementation requires structure.

Key steps include:

- creating a clear action plan

- communicating changes

- training staff

- testing the new process

- monitoring early results

Poor implementation can undo great planning. You do not want all your resources and time expended in Steps 1-8 to be flushed down the drain in one fell swoop!

Step 10: Monitor Results and Adjust

Improvement doesn’t end at implementation.

Track:

- KPIs

- error rates

- turnaround times

- employee feedback

Use the data to refine the process and lock in improvements.

Step 11: Build a Continuous Improvement Culture

Process improvement should not be a one-off event.

Continuous improvement means:

- regularly reviewing processes

- encouraging staff to flag issues

- making small, incremental improvements over time

This approach keeps businesses competitive and adaptable.

Next Steps After Process Improvement Analysis

If you’d like help assessing where improvement would make the biggest difference in your business, contact BCINC to discuss

Conclusion: Why Process Improvement Matters

Now that you can clearly answer what process improvement in business is, the value becomes obvious.

When done properly, process improvement:

- increases efficiency

- reduces frustration

- improves customer satisfaction

- supports sustainable growth

The key is structure, prioritization, and follow-through—not quick fixes.

FAQ for What Is Process Improvement in Business?

What is process improvement in business?

Process improvement in business is the structured approach to analyzing workflows, fixing inefficiencies, and improving how work gets done to achieve better efficiency, consistency, and results.

Why is process improvement important for small businesses?

Process improvement helps small businesses reduce waste, improve productivity, deliver consistent results, and scale operations without increasing chaos or over-reliance on the owner.

What are the benefits of process improvement?

The benefits include improved efficiency, reduced errors, better customer experience, higher employee engagement, lower costs, and stronger long-term business performance.

Why do process improvement initiatives fail sometimes?

Process improvement often fails due to lack of ownership, poor communication, unrealistic goals, resistance to change, or trying to fix too many processes at once.

What are the next steps after a process improvement analysis?

After analysis, the next steps are prioritizing issues, setting clear goals, implementing targeted changes, training employees, and monitoring results to ensure improvements are sustained.

References

What is process improvement? A business methodology (2019) https://www.cio.com/article/220557/what-is-process-improvement-a-business-methodology-for-efficiency-and-productivity.html