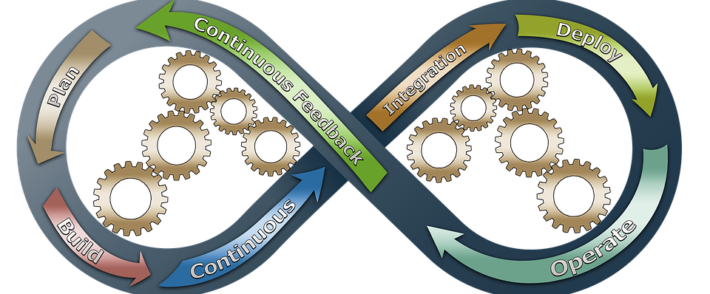

A continuous process improvement management approach helps to improve your internal processes. Your business although a stand-alone entity does not operate in isolation. It exists and functions as a multi-layered, continuously interacting system.

Most small businesses don’t struggle because people aren’t working hard. They struggle because the business is running on “patches.”

One workaround becomes two. Then five. Then the business is held together by sticky notes, memory, and whoever happens to be available that day.

That’s exactly what continuous process improvement management fixes.

This service helps you identify what’s slowing work down, remove bottlenecks, improve consistency, and build a repeatable way to improve operations over time—without turning your business into a corporate science experiment. We help you overcome common challenges in process improvement

If your team is busy but results feel inconsistent, let’s talk. We’ll pinpoint what’s breaking down and what to fix first.

What Is Continuous Process Improvement Management?

This is the structured approach to improving how work gets done in your business—step-by-step, using real data, practical observation, and repeatable improvements.

Instead of reacting to problems when they explode, you build a system that:

- identifies issues early

- fixes the root cause (not just the symptom)

- improves workflow and performance over time

- makes improvements stick, even when you’re not watching everything

This is especially valuable in trades and service businesses where small inefficiencies pile up fast—missed handoffs, rework, scheduling delays, unclear roles, and inconsistent customer experiences.

How to Implement Continuous Process Improvement Management (Without Overcomplicating It)

Most businesses don’t need a complicated improvement program. They need a simple improvement cycle that’s realistic and repeatable.

Here’s the approach we use:

1) Audit what’s happening today

We start by looking at your current workflow and the way work actually moves through your business—not the way it should move.

This often includes:

- workflow review

- process mapping (lightweight, not overly technical)

- identifying rework, delays, and breakdown points

- clarifying who owns what (and where things get dropped)

2) Fix the highest-impact issues first

We don’t try to fix everything at once. We focus on the improvements that will reduce friction quickly.

That usually means:

- eliminating duplicate steps

- tightening handoffs

- reducing waiting time

- improving scheduling and prioritization

- removing approval bottlenecks

3) Stabilize the new process(s)

A process isn’t “improved” until it runs smoothly without constant reminders.

This step includes:

- documentation (simple standard operating procedures)

- checklists or quick controls

- clear roles and accountability

- light performance tracking

4) Handoff and build internal champions

This is the value-add most businesses miss.

Instead of creating a dependency on external support forever, I train your team to become champions of continuous improvement—so they can maintain and improve processes long after the project ends.

Continuous Improvement Frameworks for Teams (That Actually Get Used)

Most improvement efforts fail because the framework is too complex, too rigid, or too disconnected from how the business runs day-to-day.

The best continuous improvement frameworks for teams are simple enough to follow when things are busy, and structured enough to prevent backsliding.

That usually means:

- one clear workflow to improve at a time

- one owner responsible for keeping it on track

- one or two measurable outcomes

- one simple way to review progress regularly

You don’t need a fancy system. You need one your team will actually stick with.

Expert Tips for Continuous Improvement Management (Without Burning Everyone Out)

Here are a few expert tips for continuous improvement management that make a big difference—especially in small businesses where time is tight:

- Keep improvements small and steady (big overhauls create resistance fast)

- Don’t “fix” what isn’t broken—focus on the real bottlenecks

- Make ownership obvious (if everyone owns it, nobody owns it)

- Measure what matters (even one metric is better than none)

- Train the team while implementing improvements (so they learn as they go)

- Review results monthly or quarterly—consistency beats perfection

Improvement doesn’t have to be dramatic. It just has to be consistent.

Challenges in Continuous Process Improvement (And How We Handle Them)

Let’s be honest—continuous improvement sounds great until real life shows up.

Some common challenges include:

- people are already busy and don’t want “extra work”

- improvements fail because nobody owns them

- teams revert back to old habits under pressure

- changes feel like criticism instead of support

- leadership wants results fast, but systems take time

The solution isn’t to push harder. The solution is to improve in a way that feels doable.

We keep improvement practical, focused, and paced properly so the business can keep running while changes are implemented.

Employee Engagement Strategies for Process Improvement (So People Don’t Tune Out)

Continuous improvement only works when your team is involved—because they’re the ones doing the work every day.

A few employee engagement strategies that work well:

- involve staff in identifying bottlenecks (they usually know exactly where they are)

- focus on removing friction, not adding rules

- explain the “why” behind changes

- give the team simple tools (checklists, templates, clearer handoffs)

- celebrate early wins to build momentum

When employees feel like improvement is being done with them, not to them, results come faster and stick longer.

What You Get (When You Hire BCINC for Continuous Process Improvement Project)

This service is for business owners who want smoother operations, fewer repeated problems, and a team that doesn’t rely on constant supervision to stay on track.

Who it’s for

This is a strong fit if you’re dealing with:

- recurring delays and rework

- regulatory non-compliances

- “we’re busy but not profitable” situations

- inconsistent service quality

- constant firefighting

- growth that’s creating chaos

- teams that are capable, but unsupported by good systems

Outcomes I help you drive

You can expect improvements like:

- faster turnaround times

- clearer accountability

- fewer repeated mistakes

- smoother workflows

- reduced operational waste

- a business that runs more consistently day-to-day

Process (what happens during the project)

Most improvement projects follow this cycle:

- Discovery and workflow review

- Process audit and bottleneck identification

- Improvement plan with priorities

- Implementation support (fixes and documentation)

- Stabilization and performance tracking

- Team training and handoff

Micro case example

A small service business I worked with kept losing time between job completion and invoicing. Everyone blamed “admin delays,” but the real issue was the handoff process—missing job notes, unclear approvals, and inconsistent documentation.

We tightened the workflow, created a simple checklist, and assigned ownership. Invoicing got faster, cash flow improved, and the owner stopped chasing paperwork every evening.

Not complicated. Just the right fix in the right place.

Want a structured improvement project that doesn’t overwhelm your team? Contact BCINC and we’ll map out your first improvement cycle.

Recommended Resources

These are practical, highly rated tools that support business planning, and implementation:

ROCKETBOOK Smart Reusable Notebook Wireless

Capture findings and action steps fast

VIZ-PRO Dry Erase Magnetic Board

Map workflows and bottlenecks visually

FAQs for Continuous Process Improvement Management

What is continuous process improvement management?

Continuous process improvement management is a structured approach to improving workflows, reducing inefficiencies, and building repeatable processes that improve business performance over time.

How long does a process improvement project take?

Most projects run from a few weeks to a few months depending on complexity, team size, and how many workflows need improvement.

What are the biggest challenges in continuous process improvement?

The biggest challenges are lack of ownership, resistance to change, unclear processes, and trying to fix too much at once without prioritizing.

How do you get employees engaged in process improvement?

Engagement improves when staff are involved early, changes reduce friction, and improvements are supported with training, clear roles, and simple tools.

Do you train teams during continuous improvement projects?

Yes. Training is a key part of the service so teams can maintain improvements and become champions of continuous improvement after handoff.

If you’re ready to stop running your business in reactive mode and start improving it in a way that actually sticks, reach out today.

REFERENCES

Cascade Team (2025): Operational Plan: Everything You Need To Know (2025 Guide) https://www.cascade.app/blog/operational-plan