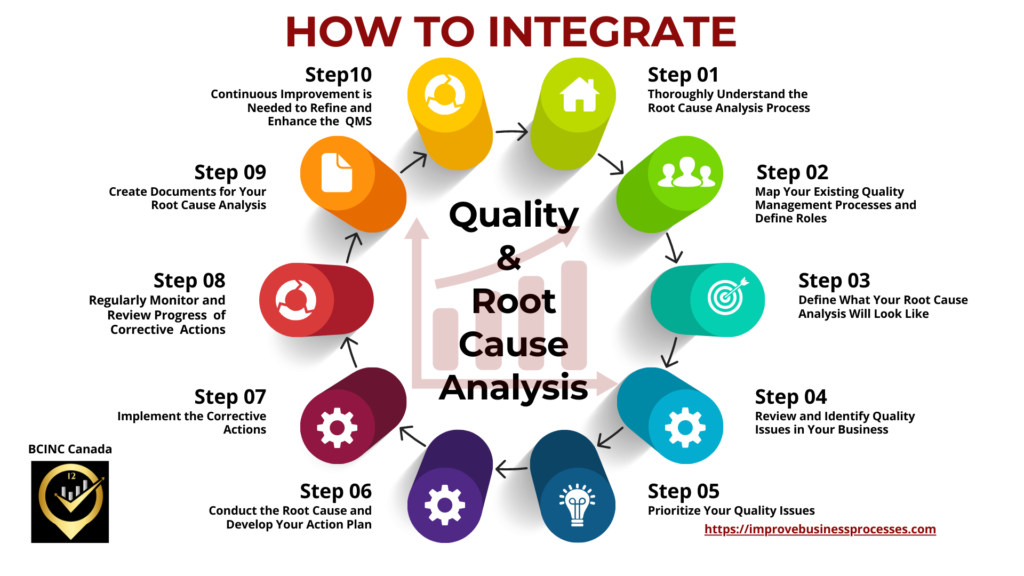

Integrating quality and root cause analysis (RCA) can greatly improve the efficiency and effectiveness of your small business quality management processes and help prevent recurring issues.

Here is a step-by-step guide on how to implement this integration.

Starting Point – Ensure Full Understanding of the Root Cause Analysis Process

Without ensuring that you and your team fully understand the intent of the root cause analysis, success will be elusive. Provide training if needed to ensure they appreciate that RCA is not a quick-fix band-aid solution used to address problems.

RCA is a powerful tool when used correctly to identify underlying causes of quality issues so that they can be addressed once and for all by applying appropriate corrective actions.

Map Existing Quality Processes

Quality and Root Cause Analysis – You have a QMS

If you already have a quality management system, the next step is easy. Review it and identify where RCA can fit in. If not, then you will need to map your existing processes to fully understand your quality related activities and when and how they are conducted.

Quality and Root Cause Analysis – You do NOT have a QMS

Unfortunately, many small businesses do not have a formal quality management system (QMS). Understand that a QMS is NOT having a couple of quality controls thrown into the production cycle! Fortunately, there is a solution for that. Read our next article – How to Integrate Root Cause Analysis and Quality Management When You Do Not Have a QMS in Place.

Define Your Desired RCA Process

Create a dedicated process for conducting RCA. This process should outline the steps to be followed, roles and responsibilities, tools to be used, and timelines for completing an RCA. Make sure it aligns with your QMS.

Identify Quality Issues

At this stage, you will need to identify all the quality related issues occurring in your business. They should not be so hard to find, as many of them are your current paint points that probably keep you up at night!

These quality related issues could be customer complaints, required re-work, defects, deviations, non-conformance, verbal only instructions etc.

Going forward, ensure that you or a delegated individual regularly monitor and track quality issues that arise within the business.

Prioritize Issues

No w that you have your laundry list of quality issues, it is time to prioritize them . Note that not all issues will require RCA. Prioritize them based on their severity, impact on the business, and frequency of occurrence.

Focus on issues that have the potential to lead to significant disruptions.

Conduct the Root Cause Analysis and Develop the Action Plan

Based on the root causes, develop actionable solutions to address them. These solutions might involve process changes, employee training, equipment upgrades, etc.

Implement Corrective Actions

Integrate the action plan into your QMS. Assign responsibilities for implementing corrective actions and set deadlines.

Monitor and Review Progress of the Corrective Actions

Regularly review the progress of corrective actions. Check if the changes are effective in preventing the recurrence of the issue. If not, go back to the RCA process to re-evaluate.

Create Necessary Documents for Your Root Cause Analysis

Document the entire RCA process, including the issue description, procedure adopted for the RCA method used, data collected, identified root causes, action plan, and results.

This documentation becomes valuable for future reference and continuous improvement and can serve as the foundation to build a QMS when you do not currently have one.

Continuous Improvement and Quality and Root Cause Analysis

Use the insights gained from your RCA to refine and enhance your QMS processes as part of continuous improvement. Do not be tempted to think that this is where it all ends.

Continuous improvement is “continuous”, so this cycle will be repeated. only this time some steps will not require any or much changes to be made. That is in fact the essence of continuous improvement – to ensure that you do not develop a “set -it -and -forget it” mindset.

Make RCA a regular part of your quality improvement efforts.

Conclusion – Integrating Quality and Root Cause Analysis

There are 10 steps in the process to integrate quality and root cause analysis in any business. Follow these steps, and see your business transform into a well -oiled and efficient machine devoid of your numerous pain points.

Related articles

- Small Business Systems – How to Increase Customer Satisfaction

- What Makes Good Customer Experience – Would You buy from You?

- Why is Customer Satisfaction so Important – It Drives Growth

- How to Integrate Root Cause Analysis and Quality Without a QMS

- Why Root Cause Analysis Tools and Techniques are Important

- How to Implement an Effective Root Cause Analysis – Plan

- Why Root Cause Analysis is Important for Continuous Improvement

- Benefits of Integrating Root Cause Analysis and Quality Management

References

What is a root cause analysis? https://www.ibm.com/topics/root-cause-analysis